Pump Industry Overview

The pump industry serves a wide range of applications, from residential water supply to complex industrial processes in sectors like mining, oil and gas, chemical manufacturing, and wastewater treatment. Pumps are essential for moving fluids through systems, and they come in various types, including centrifugal pumps, positive displacement pumps, and diaphragm pumps, each suited to particular functions and fluid types.

Key Components :

The key components in hydraulic systems include pumps, cylinders, motors, valves, hoses, and fittings, all of which work together to create efficient and powerful systems. The demand for reliable, high-performance components is crucial as these systems often operate under extreme conditions and require precise control to ensure safety, efficiency, and longevity.

Role of Precision Machined Parts in the Pump Industry

Precision machined parts are fundamental to the efficiency and reliability of pumps.

Here’s how these parts contribute:

- Critical Components: Impellers, shafts, casings, bearings, and seals are examples of pump components that require precision machining to ensure optimal performance. Any deviation in their dimensions can lead to inefficiencies or failures.

- Durability: Pumps often operate in harsh conditions, handling corrosive, abrasive, or high-temperature fluids. Precision machining enables the use of durable materials and precise fabrication techniques to produce parts that withstand these conditions.

- Energy Efficiency: Well-machined parts reduce friction and wear within pumps, leading to lower energy consumption and improved overall efficiency. This is particularly important in industries where energy costs are a significant operational expense.

- Operational Reliability: Precision in the manufacturing of pump components ensures that they fit together perfectly, reducing the likelihood of leaks, vibrations, and other issues that can cause pump failures. This reliability is crucial for maintaining continuous operation in critical applications.

Conclusion

In both the valve and pump industries, the role of precision machined parts cannot be overstated. These components are the backbone of the systems, ensuring accuracy, durability, performance, and reliability. By manufacturing high-quality precision machined parts, we provide essential support to these industries, helping them maintain efficient and effective operations in diverse and demanding applications.

The Role of Precision Machined Parts in Hydraulic Industries

Precision machined parts are the backbone of hydraulic systems. Our company specializes in manufacturing these critical components, ensuring they meet the highest standards of quality and performance. Here’s how our precision machined parts play a vital role in hydraulic industries:

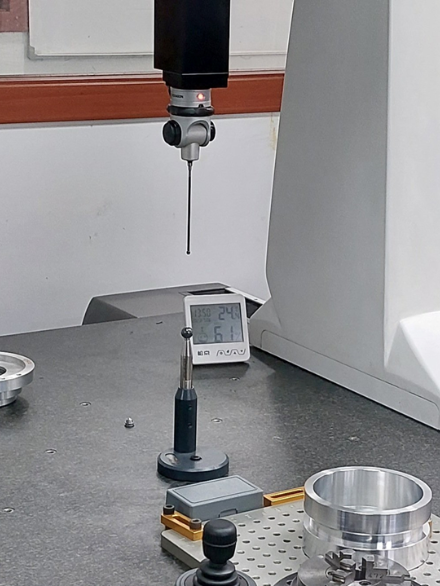

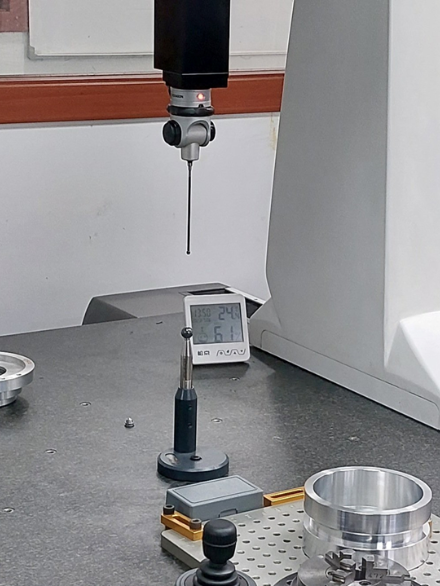

- Accuracy and Precision: Hydraulic systems require components with tight tolerances to function correctly. Our precision machining process ensures that each part is manufactured to exact specifications, providing the necessary accuracy for optimal system performance.

- Durability and Reliability: Hydraulic applications often involve high pressures and harsh environments. Our precision machined parts are crafted from high-quality materials and undergo rigorous testing to ensure they can withstand these conditions, providing long-lasting reliability.

- Efficiency: The efficiency of a hydraulic system depends on the smooth operation of its components. Our precisely machined parts reduce friction and wear, contributing to the overall efficiency of the system and minimizing energy loss.

- Customization: We understand that each hydraulic application has unique requirements. Our precision machining capabilities allow us to create custom parts tailored to specific needs, ensuring that every component fits perfectly within the system for optimal performance.

- Innovation and Technology: Staying ahead in the hydraulic industry requires continuous innovation. We leverage advanced machining technologies and techniques to produce parts that not only meet current standards but also anticipate future demands, ensuring our clients have access to the latest advancements in hydraulic components.

- Quality Assurance: Quality is paramount in the hydraulic industry. Our precision machining process includes comprehensive quality control measures, from material selection to final inspection, ensuring that every part meets stringent industry standards.

The Role of Precision Machined Parts in Hydraulic Industries

Precision machined parts are the backbone of hydraulic systems. Our company specializes in manufacturing these critical components, ensuring they meet the highest standards of quality and performance. Here’s how our precision machined parts play a vital role in hydraulic industries:

- Accuracy and Precision: Hydraulic systems require components with tight tolerances to function correctly. Our precision machining process ensures that each part is manufactured to exact specifications, providing the necessary accuracy for optimal system performance.

- Durability and Reliability: Hydraulic applications often involve high pressures and harsh environments. Our precision machined parts are crafted from high-quality materials and undergo rigorous testing to ensure they can withstand these conditions, providing long-lasting reliability.

- Efficiency: The efficiency of a hydraulic system depends on the smooth operation of its components. Our precisely machined parts reduce friction and wear, contributing to the overall efficiency of the system and minimizing energy loss.

- Customization: We understand that each hydraulic application has unique requirements. Our precision machining capabilities allow us to create custom parts tailored to specific needs, ensuring that every component fits perfectly within the system for optimal performance.

- Innovation and Technology: Staying ahead in the hydraulic industry requires continuous innovation. We leverage advanced machining technologies and techniques to produce parts that not only meet current standards but also anticipate future demands, ensuring our clients have access to the latest advancements in hydraulic components.

- Quality Assurance: Quality is paramount in the hydraulic industry. Our precision machining process includes comprehensive quality control measures, from material selection to final inspection, ensuring that every part meets stringent industry standards.