Valve Industry Overview

The valve industry is critical to various sectors, including oil and gas, water and wastewater management, power generation, chemical processing, and many more. Valves regulate, direct, or control the flow of fluids (gases, liquids, fluidized solids) by opening, closing, or partially obstructing passageways. They come in various types, such as gate valves, globe valves, ball valves, butterfly valves, and check valves, each designed for specific applications and performance criteria.

Key Components :

The key components in hydraulic systems include pumps, cylinders, motors, valves, hoses, and fittings, all of which work together to create efficient and powerful systems. The demand for reliable, high-performance components is crucial as these systems often operate under extreme conditions and require precise control to ensure safety, efficiency, and longevity.

Role of Precision Machined Parts in the Valve Industry

Precision machined parts are essential to the valve industry, ensuring the valves’ functionality, reliability, and longevity.

Here are key ways these parts play a critical role:

- Accuracy and Fit: Precision machining ensures that components such as valve bodies, spindles, seats, and disks are manufactured to exact tolerances, which is crucial for the tight seals and smooth operation required in valve systems.

- Material Compatibility: Different applications demand materials with specific properties (e.g., corrosion resistance, high strength, and temperature tolerance). Precision machining allows for the fabrication of parts from various materials, ensuring compatibility with the intended application.

- Enhanced Performance: High-quality machined parts minimize wear and tear, reducing the need for maintenance and increasing the operational efficiency of valves. This reliability is vital in industries where downtime can be costly and hazardous.

- Customization: Precision machining provides the flexibility to produce custom valve components tailored to specific industry needs, ensuring optimal performance in unique operating conditions.

By providing high-quality, precision machined parts, we support the hydraulic industry’s need for reliable and efficient systems. Our commitment to excellence ensures that our clients can depend on our components for their most demanding applications, helping them achieve their goals and maintain a competitive edge in their respective fields.

The Role of Precision Machined Parts in Hydraulic Industries

Precision machined parts are the backbone of hydraulic systems. Our company specializes in manufacturing these critical components, ensuring they meet the highest standards of quality and performance. Here’s how our precision machined parts play a vital role in hydraulic industries:

- Accuracy and Precision: Hydraulic systems require components with tight tolerances to function correctly. Our precision machining process ensures that each part is manufactured to exact specifications, providing the necessary accuracy for optimal system performance.

- Durability and Reliability: Hydraulic applications often involve high pressures and harsh environments. Our precision machined parts are crafted from high-quality materials and undergo rigorous testing to ensure they can withstand these conditions, providing long-lasting reliability.

- Efficiency: The efficiency of a hydraulic system depends on the smooth operation of its components. Our precisely machined parts reduce friction and wear, contributing to the overall efficiency of the system and minimizing energy loss.

- Customization: We understand that each hydraulic application has unique requirements. Our precision machining capabilities allow us to create custom parts tailored to specific needs, ensuring that every component fits perfectly within the system for optimal performance.

- Innovation and Technology: Staying ahead in the hydraulic industry requires continuous innovation. We leverage advanced machining technologies and techniques to produce parts that not only meet current standards but also anticipate future demands, ensuring our clients have access to the latest advancements in hydraulic components.

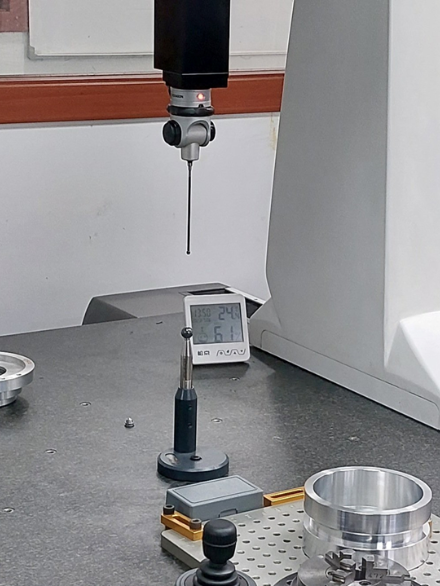

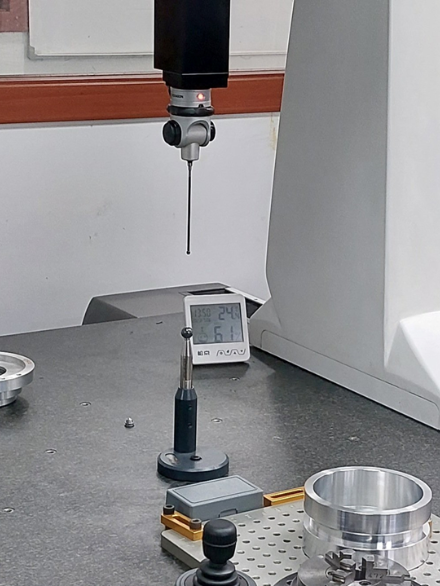

- Quality Assurance: Quality is paramount in the hydraulic industry. Our precision machining process includes comprehensive quality control measures, from material selection to final inspection, ensuring that every part meets stringent industry standards.

The Role of Precision Machined Parts in Hydraulic Industries

Precision machined parts are the backbone of hydraulic systems. Our company specializes in manufacturing these critical components, ensuring they meet the highest standards of quality and performance. Here’s how our precision machined parts play a vital role in hydraulic industries:

- Accuracy and Precision: Hydraulic systems require components with tight tolerances to function correctly. Our precision machining process ensures that each part is manufactured to exact specifications, providing the necessary accuracy for optimal system performance.

- Durability and Reliability: Hydraulic applications often involve high pressures and harsh environments. Our precision machined parts are crafted from high-quality materials and undergo rigorous testing to ensure they can withstand these conditions, providing long-lasting reliability.

- Efficiency: The efficiency of a hydraulic system depends on the smooth operation of its components. Our precisely machined parts reduce friction and wear, contributing to the overall efficiency of the system and minimizing energy loss.

- Customization: We understand that each hydraulic application has unique requirements. Our precision machining capabilities allow us to create custom parts tailored to specific needs, ensuring that every component fits perfectly within the system for optimal performance.

- Innovation and Technology: Staying ahead in the hydraulic industry requires continuous innovation. We leverage advanced machining technologies and techniques to produce parts that not only meet current standards but also anticipate future demands, ensuring our clients have access to the latest advancements in hydraulic components.

- Quality Assurance: Quality is paramount in the hydraulic industry. Our precision machining process includes comprehensive quality control measures, from material selection to final inspection, ensuring that every part meets stringent industry standards.